Project summary

This was an open-ended project I worked on for my Thermal Fluid Systems II class. We were tasked to use Computational Fluid Dynamics (CFD) to analyze the fluid and heat transfer properties relevant to a flow of our choice. Do to our involvement in the Tufts Solar Vehicle Project (TSVP), my partners and I decided to analyze a problem that was both highly interesting and relevant to the team – the flow through an air-cooled lithium-ion battery pack. The results were very insightful, and led us to conclude a redesign of the pack was necessary.

How I did it

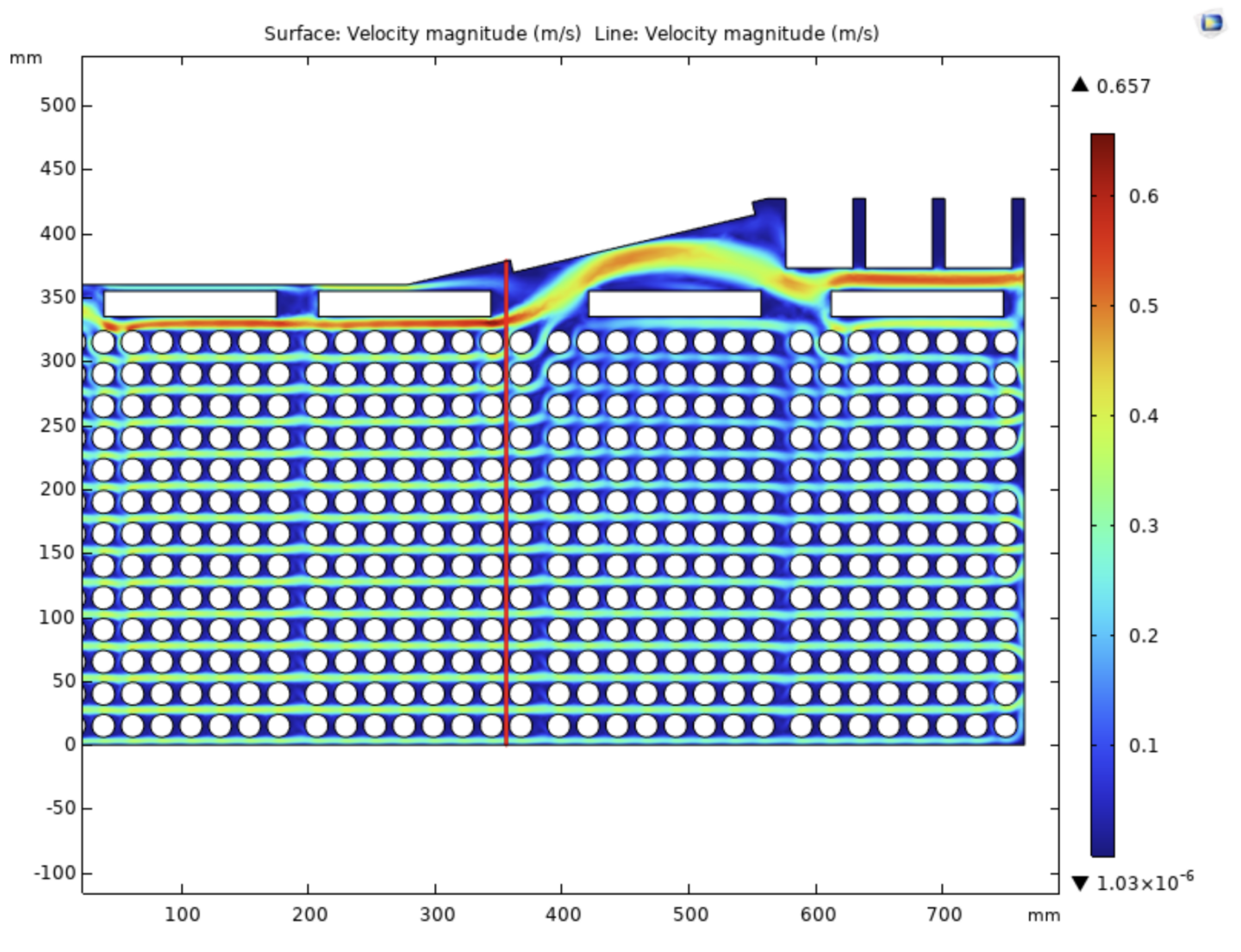

In the first part of the project, we simulated in 2D and 3D fluid flow through the battery pack the team had prior designed, using reference fan specifications. We found that flow through the pack was not optimal, as a large amount of the flow was being diverted away from the cells nearest the outlet, thus not being useful for cooling.

In the second part of the project, we simulated heat transfer throughout the battery pack to determine 1) the maximum cell temperature and 2) the maximum temperature difference in the enclosure. We found the max cell temperature to be 213 C and the max temperature difference to be 153 C, both far above permissible limits – indicating a redesign was in order.

Possible inaccuracies with the study arise from the fact that we used an extremely course mesh, L-VEL turbulence model (which is considered among the most computationally robust yet least accurate), and a time-independent/steady-state analysis. On the last point, this indicates that the values derived from the study represent a situation where the pack has heated up to the extent that the rate of energy gain in the pack is equal to the rate of energy loss. Such a situation is highly unlikely to occur in normal usage, as the pack only operates at its peak power output (and thus heat generation) during short bursts, such as needed during overtaking.

You can see the full report with pictures here or below: